STRUC-RITE : Metal Building System.

Our Patrons

·

Abis Export Pvt. Ltd.

·

Amit Agro

·

Ashoka Aluminum

·

Balaji Engineering

·

GSB Refractory

·

Hira Power

·

Indian Oil Corporation Ltd.

·

Indo-Sap Engineering Pvt. Ltd.

·

Khetawat Industries

·

Mahindra Motors

·

R.S Food processors

·

Sarda Dairy & Food Products Pvt. Ltd.

·

Sarda Enery & Minerals Limited.

·

Siddhi Agro

·

Vossloh BK Casting

Application

·

Warehouse

·

Industrial Building

·

Indoor Tennis Courts

·

Petrol Pumps

·

Showrooms

·

Shopping Centers

·

Restaurants

·

Multiplexes

·

Offices

·

Swimming Pool Enclosures

·

Car parking sheds

·

Poultry-Dairy Farms

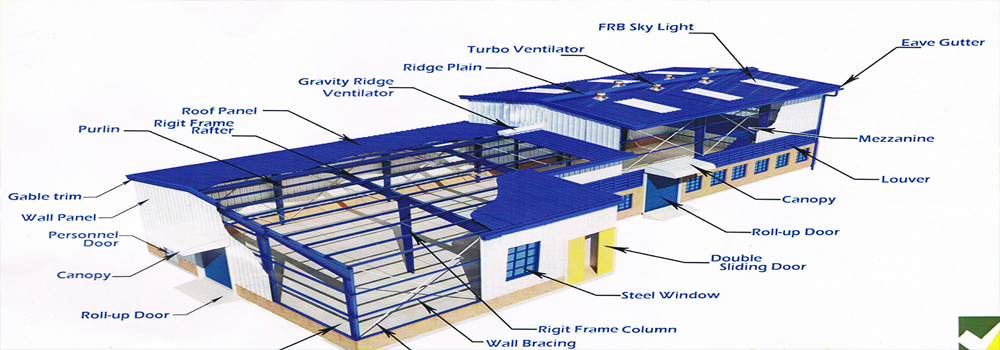

PRE-ENGINEERING BUILDINGS:

A pre-engineering building (PEB) is designed to be

fabricated using best suited raw materials and manufacturing methods that can efficiently

satisfy a wide range of structural and aesthetic design requirements.

Historically, the primary framing structure of a

pre-engineering building is an assembly of I-shaped members. Often referred as

I-beams. In pre-engineering building, the I beams used are usually formed by

welding together steel plates to form the I section. The I Beams are then

field-assembled (e.g. bolted connections) to form the entire frame of the

pre-engineering building.

An efficiently designed pre-engineering building can be lighter

than the conventional steel buildings by up to 30%. Lighter weight equates to

less steel and a potential price savings in structural framework.

PEBs are resistant to moisture, adverse weather conditions,

earthquakes, termites and fire. They provide lifelong durability, safety and

very low cost-maintenance.

Key Benefits of PCBS are:

Reduced construction time

Flexibility of Expansion

Large Clear Spans

Low Maintenance

Energy Efficient Roofing and Wall

PEB Vs Conventional Building

PCB

·

Structure weight is 30% less through efficient

use of steel.

·

Columnless large spans are possible.

·

Factory controlled quality.

·

Lower initial cost ( cost per square meter is

about 30% less than the conventional constructions) and faster delivery.

·

Unique architectural designs can be achieved at

low cost.

·

Seismic Resistance: The low weight flexible

frames offer higher resistance to seismic forces.

·

Delivery time is average 6-8 weeks.

·

Foundation: Simple design, easy to construct and

light weight.

·

Aesthetically appealing appearance at a lower

cost.

·

By following the international design standard

& codes using standard sections and connections reduce the design time

drastically.

Conventional Building

·

Practice of excessive safety factor and the

usage of heavier steel sections keep the weight high.

·

Every project has to start from the beginning

and to be fabricated at site.

·

Cost is more and delivery takes more time.

·

Special design and features must be developed

for each project and at a higher cost.

·

Rigid heavy weight structures do not perform

well in seismic zones.

·

Delivery time is average 22-28 weeks.

·

Extensive heavy foundation is required.

·

Special aesthetic design may increase the cost.

·

Each structure is designed from scratch and

availability of the design aids are less, thus increase the design time.